Product introduction

SCF flotation machine has two forms of DC tank and suction tank, the main difference is the impeller structure; The DC tank adopts a single blade impeller, which can produce large circulation of pulp in the tank and good air dispersion effect. A bidirectional blade impeller is adopted in the suction groove, which is based on the DC groove impeller and adds a small blade that plays the role of suction. The blades of the two types of impellers are inclined back to a certain Angle, but the lower blade height of the pull-sucking impeller is smaller than that of the straight flow impeller. The practice has proved that the impeller with this structure has weak stirring force, large pulp circulation and low power consumption, and the combined action with the tank and lattice plate can fully ensure the suspension and air dispersion of coarse minerals.

Working principle

The flotation machine is a mechanical equipment for separating solid minerals by flotation method. When the flotation machine is working, driven by the motor, the main shaft drives the disk to rotate slowly, and the pulp enters the feeding disk from the feeding tank and is evenly distributed to the surface of the pulp under the action of centrifugal force. Among the rotating disc blades, the pulp is squeezed by the blades and partially backflow to form eddy currents. The pulp flow is evenly dispersed on the leaves. Due to the addition of inhibitors and collectors to the ore, the target mineral particles form negatively charged pseudoconjuncts in the ore pulp. These negatively charged particles are uniformly adsorbed on the disc blade under the action of electrostatic gravity and rotate with the disc together with gangue particles. The ore particles attached to the lower surface of the blade are in a suspended state due to the rinsing of the superserum. Under the combined action of centrifugal force, fluid power and electrostatic gravity, the gangue particles are washed away, while the target mineral particles are left in a suspended state and transferred to the upper part of the disc to be rinsed and enter the cleaning operation.

Advantages and characteristics

1, processing the maximum mineral particle size of 1mm;

2, the groove is provided with a lattice plate, so that the pulp surface is stable, improve the technical performance;

3, good air dispersion, large air capacity, low power consumption;

4, pulp circulation is good, do not sink when dealing with coarse materials;

5, with ore slurry level automatic control system, easy operation and management;

6, the coarse particle flotation machine is equipped with a slurry suction tank, the flotation operation can be horizontally configured, eliminating the foam pump for the return of the ore.

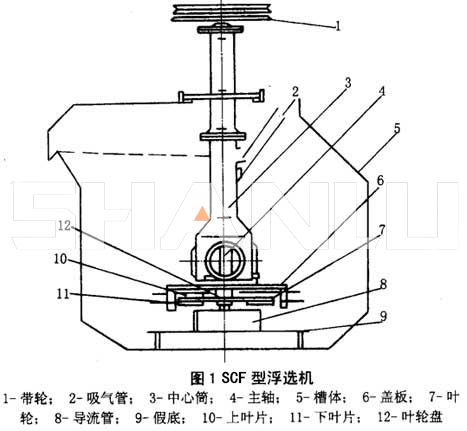

Flotation machine product structure diagram

Equipment display