High purity quartz sand concept

Quartz is one of the most widely distributed minerals on the earth's surface. The main composition is SiO2, with a Mohs hardness of 7, a specific gravity of 2.65, and a melting point of 1750 ℃. Pure quartz is colorless and transparent, because it contains trace pigment ions or fine dispersed inclusions, or there is a color center and a variety of colors, and the transparency is reduced and becomes translucent or opaque crystal, hard texture.

What is high purity quartz sand?

In fact, there is no clear standard for the concept and classification of high purity quartz sand in China. Based on the views of researchers and the current international technical level, we can call the quartz sand with purity w (SiO2) ≥3 N~5 N and w (Fe2O3) < 10x10-6 as high purity quartz sand, and call 6N-7N as super high purity quartz sand.

Note: 3 N~5 N refers to SiO2 content 99.9~99.999; 6N-7N refers to SiO2 content 99.9999~99.99999.

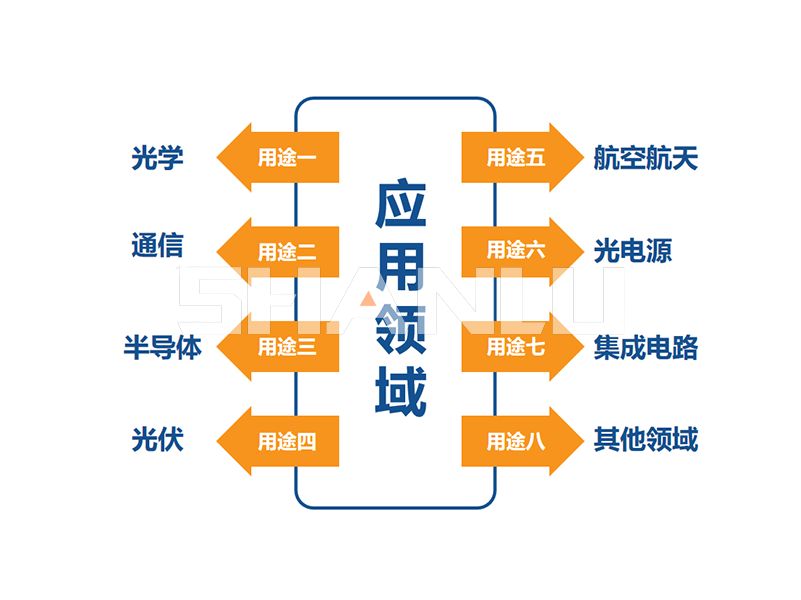

Application of high purity quartz sand

The main composition of high purity quartz sand is SiO2. With high purity quartz sand as raw material, it can produce quartz glass crucible, ingot, pipe, bar, plate, all kinds of utensils and devices as well as quartz glass fiber and fabric and other high purity quartz products.

High purity quartz material is an indispensable key basic raw material in glass, electronics and electrical appliances, quartz glass and other high-end technology fields, which is used in important fields supporting the development of strategic emerging industries, such as semiconductor, optical communications, photovoltaic, optics, electric light sources, etc. These characteristics make it play a very important role in modern industry and high-tech fields.

General processing technology of high purity quartz sand

1.Beneficiation; 2. Water quenching; 3. Magnetic separation; 4. Flotation; 5. Acid leaching; 6. High temperature vacuum treatment; 7. Chlorination; 8. Electric separation; 9. Superconducting magnetic separation.

Equipment display