What is quartz powder?

Quartz powder generally refers to silicon powder. Quartz powder is made of pure quartz (natural quartz or fused quartz) through crushing, picking, cleaning, acid treatment, high temperature melting, medium crushing, fine grinding, grading, iron removal and other processes to meet the requirements of the powder.

Processing and production mode

Quartz powder is divided into two production methods: dry method and water method, various conventional specifications: 100M, 150M, 200M, 325M, 400M, 600M, 1500M and 2000M(M is the mesh number). In addition, it can also be processed according to customer requirements, and the requirements of particle size distribution can also be processed.

Quartz powder category

Industrial quartz powder (sand) is often divided into: ordinary quartz sand (powder), refined quartz sand, high purity quartz sand, molten quartz sand and silica powder.

Scope of application

Quartz powder has no grades, only specifications. Because of its high whiteness, no impurities, low iron content, it has a wide range of applications.

1. Glass: the main raw materials of flat glass, float glass, glass products (glass jars, glass bottles, glass tubes, etc.), optical glass, glass fiber, glass instruments, conductive glass, glass cloth and special anti-ray glass;

Second, ceramics and refractory materials: porcelain embryo and glaze, kiln with high silicon bricks, ordinary silicon bricks and silicon carbide and other raw materials;

Third, construction: concrete, cementitious materials, road building materials, artificial marble, cement physical properties test materials (i.e., cement standard sand);

4. Chemical industry: raw materials of silicon compounds and water glass, filling of sulfuric acid tower, amorphous silica powder;

5, machinery: the main raw materials of casting sand, grinding materials (sandblasting, hard grinding paper, sandpaper, emery cloth, etc.);

6. Electronics: high-purity metal silicon, optical fiber for communication, etc.;

7, rubber, plastic: fillers (can improve wear resistance);

8, paint: filler (can improve the weatherability of paint);

9, metallurgy: silicon metal, ferrosilicon alloy and silicon aluminum alloy and other raw materials or additives, fluxes;

10, aviation, aerospace: its internal molecular chain structure, crystal shape and lattice change law, so that it has high temperature resistance, small thermal expansion coefficient, high insulation, corrosion resistance, piezoelectric effect, resonance effect and its unique optical characteristics.

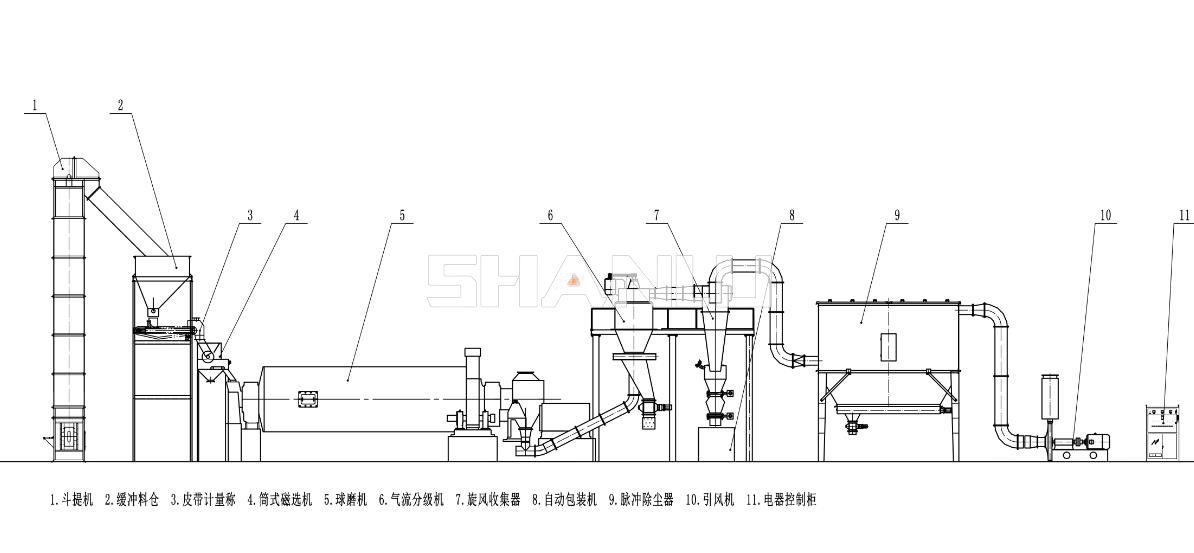

Process flow chart

Equipment display