Quartz sand wet process production line working video

您的浏览器不支持 HTML5 video 标签。

Product introduction

This production line is mainly suitable for the production of light glass sand, float glass sand, daily glass sand, quartz sand and potassium albite sand powder for oil fracturing.

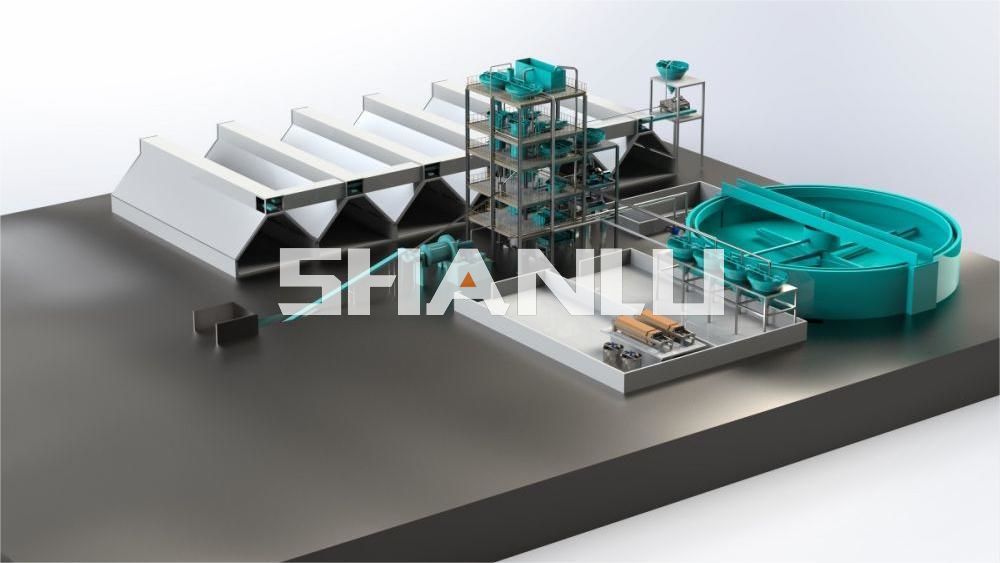

The production process is as follows: the raw ore is crushed to 30mm or less by crushing equipment such as jaw breaker and cone breaker. The raw material less than 30mm goes into the rod mill or other sand making equipment to make sand. The mortar produced by the mill is separated by the hydraulic classifier and the blocked settler, and the qualified particle size of 26-140 mesh is separated. Qualified particle size of quartz sand into the magnetic separator for iron removal purification; The finished sand after magnetic separation is dehydrated by the dewatering screen and then hit to the finished product warehouse for stacking; Tail mud and tailings are separately stacked. Water can be recycled, and the entire production process is environmentally friendly and pollution-free.

The design of the process is mature and the operation is stable and reliable. The company can according to the customer's raw ore grade, output, product standards and other requirements, customized production lines for customers. Annual output from 50,000 tons to 1 million tons can be achieved.

Process flow chart

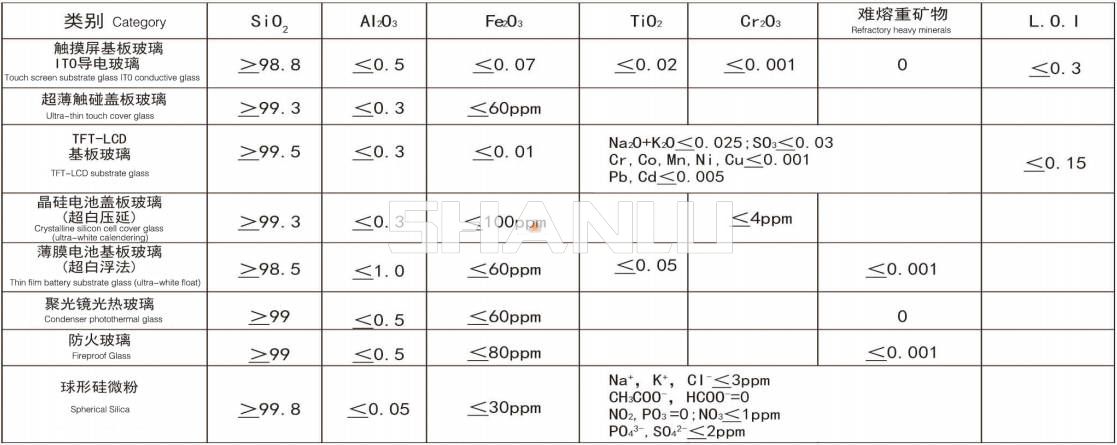

Classification and application of common quartz sand

The main varieties of glass sand: in the domestic market, w(SiO2)99% of quartz sand products, according to its T(Fe) content: w(TFe)≤0.08% of Pu sand; w(TFe)≤0.05% fine sand; w(TFe)≤0.01% low iron quartz sand. The price difference between them is several times.

w(SiO2)99% or so products: glass sand (float glass, daily glass, glass fiber, etc.), ceramics, casting sand, oil proppant sand, and refractory materials, metallurgy, metal silicon, etc. Its characteristics are not high unit price, but the amount is very large, industrial output value is very considerable.

Glass sand market: At present, the total industrial output value of China's daily glass products (glassware, glass insulation containers, glass packaging containers, etc.) has reached more than 200 billion yuan, and the total output has reached 30 million tons. That's 40 percent more than five years ago, with a compound growth rate of 8 percent. Sichuan glass industry demand for quartz sand is 6 million tons/year.

w(SiO2)>99.9% products: This is the highest value-added quartz application area, including high purity quartz and its glass products. High purity quartz is the general name of silica series products with purity greater than 99.9%. The product grade can be divided according to the purity of SiO2: low-end w(SiO2)> 99.9% (3N); Middle w(SiO2) > 99.99% (4N); High-end w(SiO2)> 99.998% (4N8).

Quartz sand technical indicators refer to the table

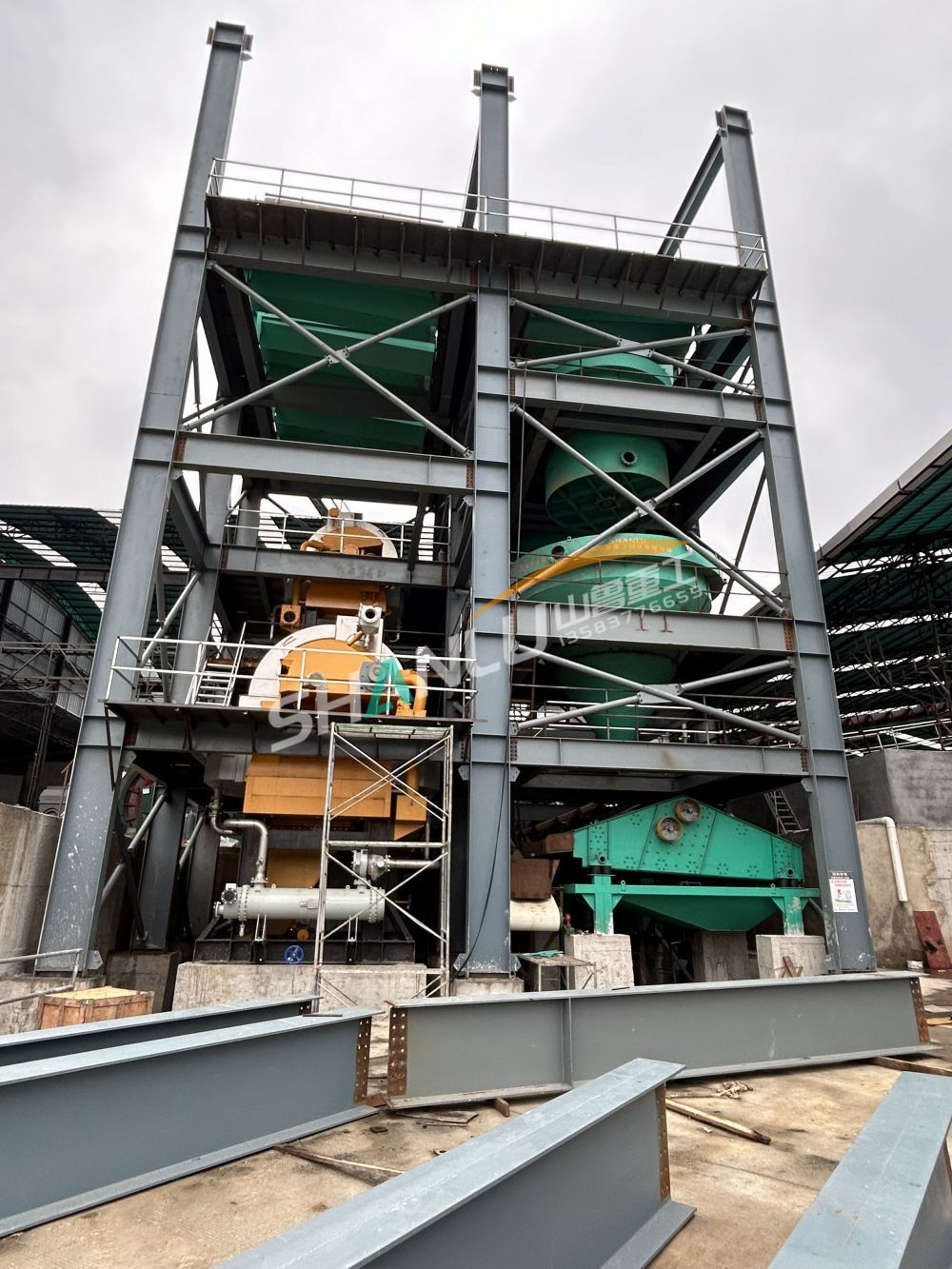

Equipment display